Polymer Melt Filters

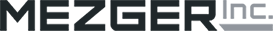

In the process of producing synthetic fibers, especially filament POY /FDY/ BCF/staple fiber/ nonwoven spinning, before polymer access to spinnerets, all the foreign substance has to be filtered. Meanwhile the polymer should be not leaked out of spin pack containers. MEZGER,INC. can offer you a complete set of elements used inside spin pack body, such as spin pack filters, wire mesh, gaskets, etched photo film and more.

We offer a wide range of filtration products for polymer melt processing.

Gaskets

- Aluminum

- Copper

- Nickel-plated copper

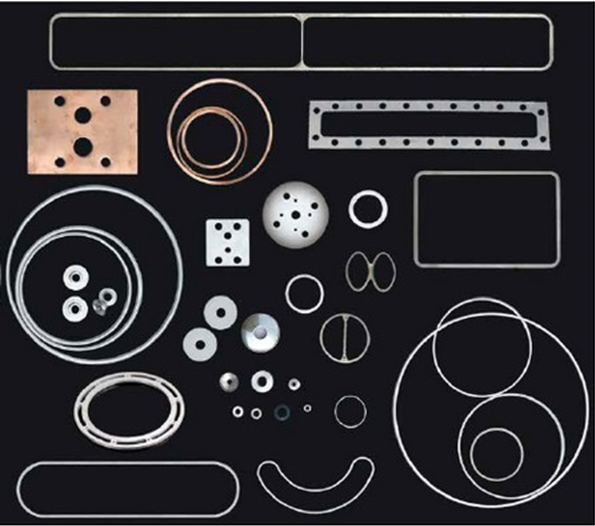

Framed Filter Screens

• any layers with different mesh

• any shapes with different frame alloys available

• spot weld pack available

• different filter media

• any shapes with different frame alloys available

• spot weld pack available

• different filter media

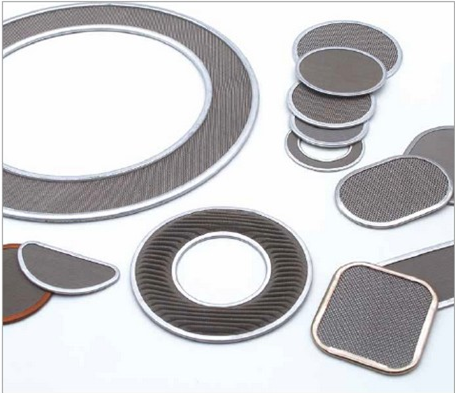

Single and Point Welded Filter Screens

Based on our rich experience and knowledge, we can select filtering media and its structure, which is suitable for your application.

• Polymer flow through filter media easily

• Long lifespan

• Facilitate handling and maintenance

• Polymer flow through filter media easily

• Long lifespan

• Facilitate handling and maintenance

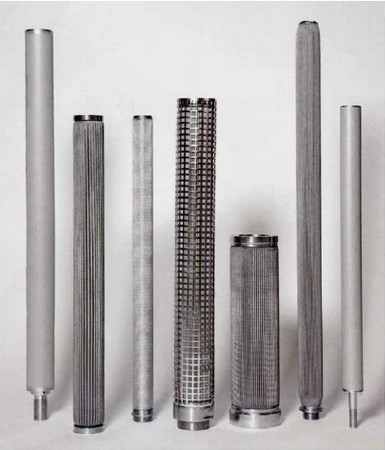

Candle Filters

The candle filter can be designed to be fixed or removable, where mesh pack layers can be dismantled and replaced by a new one. It will save you money and time because you only need to replace mesh pack layers after the filter can’t be used any more.

Stainless Steel Sand

The metal sand filled in spin pack for filament and staple fiber spinning should contain two or three layers with different powder particle sizes and quantity. The best combination of particle sizes mainly depends on the type of polymer used in the spinning process, its viscosity and purity, melt temperature and extrusion velocity. The filtration grains are made of stainless metal alloys which are specially developed for hot polymer filtration. Iron, as basic element, is used to provide good strength in order to avoid brittleness of these particles during filtration under the condition of high pressure and hot environment, therefore decrease the risk of spinnerets capillary clogged. But other alloy elements such as chromium, nickel, silicon and Mn are added necessarily for improving strength and high porosity.

Technical Specification

We can supply any type of particles size combination as requested. The common used mesh size is as follows.

|

Size Mesh

|

Size Micron

|

Density(g/cm3)

|

Porosity %

|

|

10-20

|

2000-850

|

1.5

|

75

|

|

20-40

|

850-350

|

1.7

|

73

|

|

40-60

|

350-250

|

1.8

|

71

|

|

60-80

|

250-180

|

2.0

|

64

|

|

80-100

|

180-145

|

2.1

|

63

|

|

100-120

|

145-125

|

2.3

|

60

|