Spinneret Inspection & Microscopes

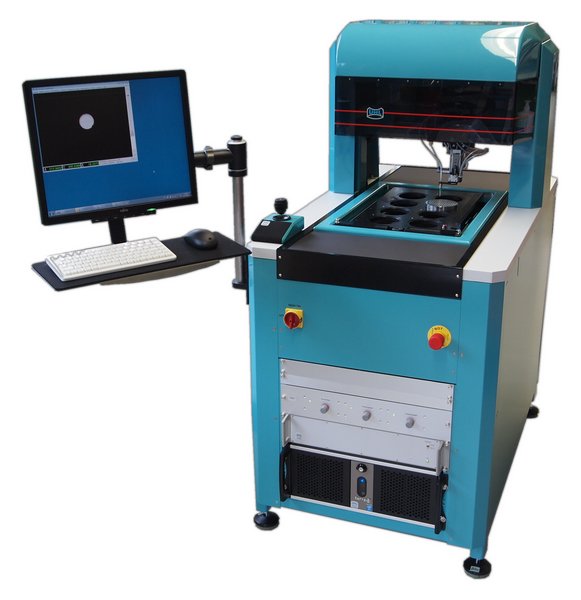

We offer a complete range of inspections systems for all types of spinnerets ranging from simple manual systems, to completely automated versions.

- Improve product quality and avoid secondary product problems

- Save labor cost

- Used as factory-entry quality detection for new spinneret

- Determine the usage years and quality of old spinnerets

- Assess the yield rate of cleaning equipment

- Instantly assess and improve abnormal spinning process phenomena

- Recover equipment costs within a short time

Founded in 1943 by Oskar Uhl, Walter-Uhl is a traditional precision engineering company. They have long-term experience, continous enlargement respectively further development of their product range, and became a worldwide leader for high-quality optical measuring technique. They have in-house design, software development, and manufacturing facilities.

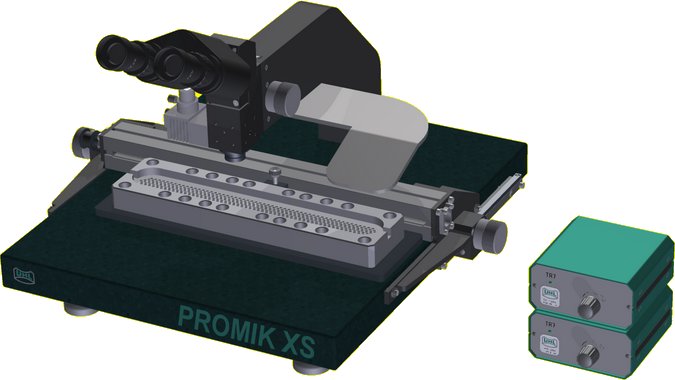

Small Devices

Among our small devices are the Rod Microscopes SM, the Portable Microscopes MS1 and TM2, the Centering Microscopes ZM1 and the Alignment Tester FLZ for machine bearing alignment (straightness measurement). All devices are manufactured and assembled in-house as a high valuable product "Made in Germany". Upon request, custom solutions are possible anytime.

Portable Microscope MS1Valuable, portable measuring microscope with integrated coaxial and angular incident illumination. • steady, anodized aluminium body • focussing by knurled ring and fine-pitch thread • transformer with LED or battery LED lamp Options: • digital screw micrometre eyepiece for precise distance measurement • digital z-measurement device for depth measurement, integrated in the body • high resolution digital USB video camera VM4-USB • measuring software VMS-USB |

|

|||||||||||||||||||||||||||||||||||||||||||||||||

Measuring Microscope TM2The portable measuring microscope TM2 is used to measure structues on rollers and flat or cylindric products with 3 digital axes (X/Y/Z) - self contained with integrated batteries. • solid v-block base for stable attachment • rubber coated surface protects the product against scratches and damage • eyepiece with diopter compensation and crosshair with concentric circles • coaxial coarse / fine movement for focussing |

||||||||||||||||||||||||||||||||||||||||||||||||||

Alignment Tester FLZPortable measurement microscope for the alignment of machine bearings. The measuring wire ist fastened to the headstock or a special holding device, fed at the end of the base over a pulley and stretched tight with a weight (layout according to DIN 8606). The alignment tester must be placed on the carriage of the machine or a corresponding device, which can be moved in a longitudinal direction in predefined steps on the machine base. The measuring wire must be aligned in such a way that the same values are measured in the starting and end position of the carriage, i.e. that it is tensioned to form an imaginary connecting line parallel to these positions. When the wire is aligned to the bearing, the value display is set to zero. The straightness deviation can now be read directly on the display for each position when both parts of the image are fitted together by moving the microscope horizontally with the integrated micrometer spindle. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||

Machine Centring Microscope MZMUniversal centring microscope to set up tool machines (for example milling or drilling machines). The edges of a workpiece can be positioned, rotary stages can be centered or machine spindles can be aligned. The centring microscope is fixed in the machine instead of the tool. • DIN 2080-A 40 (short taper) standard fixture • different fixtures and draw bolt upon request |

|

|||||||||||||||||||||||||||||||||||||||||||||||||

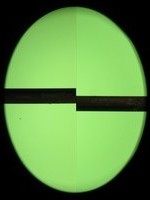

Spinneret Inspection Microscopes• high mechanical stability for long term inspection- and, due to that, spinning-quality. • excellent optical image quality for fatigue-proof operation • half- or fully-automatic inspection in combination with motorized axes improves the efficency and reduces operator influence • by using the UHL component system, the Inspection Microscopes can be easily customized and provide simplified maintenance • the PM4, PR5, PR7, PR8 and PR9 Inspection Microscopes are providing a direct, alternating view of capillary and counterbore without moving the spinneret • several instrument types provide the fast inspection during stage movement with a large field of view with a speed of up to 2300 capillaries per minute • inspection through the entire capillary length during the focusing travel |

|