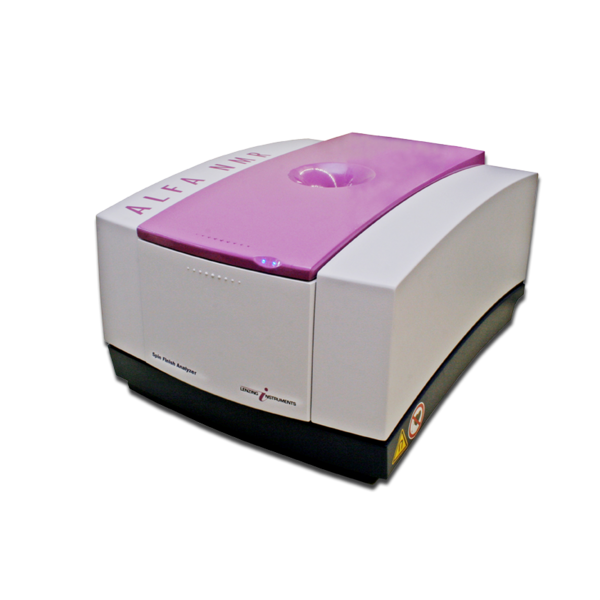

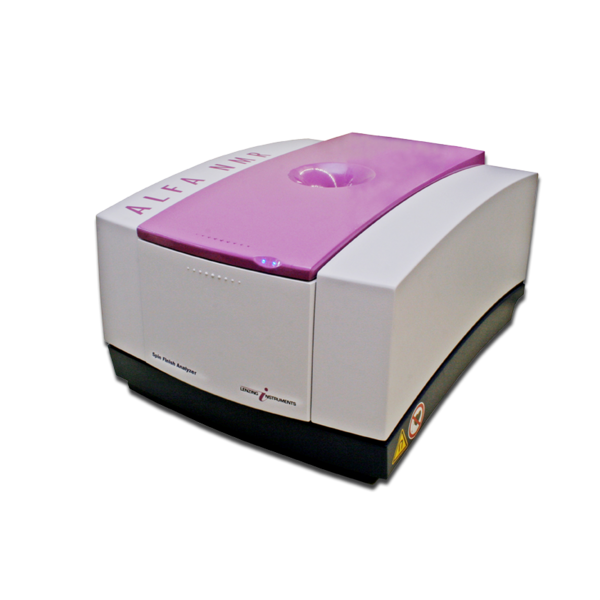

Spin Finish : ALFA 500

Spin finish level determination (OPU%), based on the extraction method - ppm of carbon particles

- Measurement per sample only 3 minutes

- Automatic measurement of 28 samples

- Dissolvent is hot deionized water – no harmful chemicals

|

|

Spin Finish : NMR

Spin finish level determination (OPU%), based on the NMR method

- Fast measurement – a few seconds per sample

- Solvent free analysis

- Special unbreakable sample tubes for fast and safe sample loading

- The spin finish content may be analyzed with the weighless method or the weighing method

|

|

Duratech ASP 960 : Autosampler

Gantry-style, cartesian robot that automates the handling of sample tubes and vials for use in numerous laboratory applications.

- Fail-safe custom tube gripper, an adjustable shelf and an easy-to-use interface

- 9-pin serial port for RS-232 communications with a computer

- available for standard tube sizes from 10mm to 60mm

- customization available for other tube sizes and applications

- works well with our TCON Dry Bath Temperature Controller product line and with various third-party Benchtop NMRs

|

|

Spin Finish : Oil Extraction

Manual apparatus to determine oil content of fibers, yarn and nonwovens. Digital temp. controller reaches the required set points in about 15min.

|

|

Linear Density / Evenness : ACW600 / DVA

Fully automated measurement of denier/dtex and evenness of filament yarn especially designed for production control

- Expert system for most efficient use in production control

- In combination with DTI600 covering the most crucial properties of filament yarn

- Fully automatic string-up and measurement

- Best efficiency in combination with SESS/LENSESS

- Extra fast, only 35 seconds per test

- Developed in cooperation with DuPont

- Complies with ASTM D6612 and D6587

|

|

Sample Collector : ASC12

Sample collector in combination with ACW600 for subsequent tests with the ALFA 300

- Collecting samples from ACW which are perfectly prepared for spinfinish test

- No additional sample preparation

- Faster preparation of ALFA test

- Less mistakes

|

|

Sampling System : SESS

Bobbin handling system – making the tests on ACW600/DVA, DTI600 and RAPID 600 even more efficient

- Bobbins directly measured from the trolley/buggy

- Automatic management of set-up data

- Professional database and operation software

- Designed for all levels of transport systems and automation

- Developed in cooperation with DuPont

|

|

Draw Tension : DTI600

Fully automated measurement of the regularity of the molecular orientation by the measurement of the draw tension of filament yarn especially designed for production control

- Expert system for most efficiency in production control

- Prediction of performance quality of POY for texturing, dyeing, drawing – best in combination with ACW600/DVA

- Best efficiency in combination with SESS/LENSESS

- Developed in cooperation with DuPont

- The measurement method complies with ASTM D5344.

|

|

Interlace : Rapid600V

Fully automated measurement of number and tenacity of Interlaces/Entanglements of filament yarn especially designed for production control

- Expert system for most efficient use in production control

- Fully automatic string-up and measurement

- Evaluating number and tenacity of interlaces

- Mostly used for POY, FDY, technical yarns

- Developed in cooperation with DuPont

- Complies with ASTM D4727

|

|

Spin Finish : Opumeter

Hand held instrument for quick checks of the OPU/FOY (Oil Pick Up/Finish On Yarn) value on the running yarn

- Online, real time control of the spin finish content

- Non-contact measurement

- No special preparations necessary

- Fast measurement – a few seconds per measurement

- Lightweight and easy to use handheld instrument

- Results evaluation by means of the OPUMETER card reader software

|

|

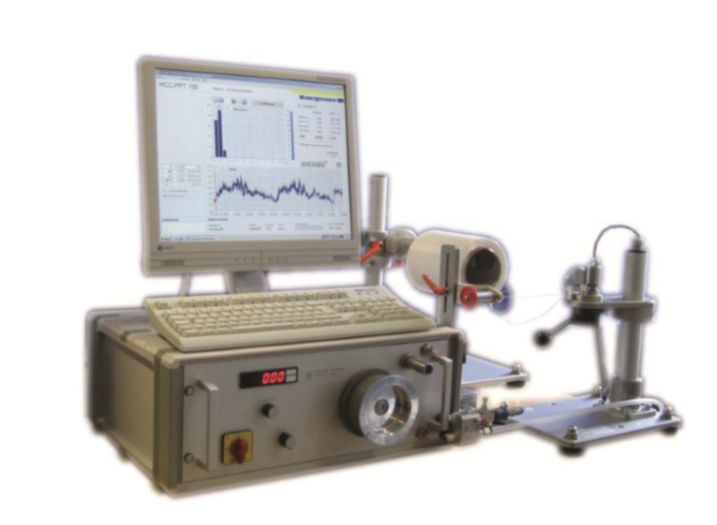

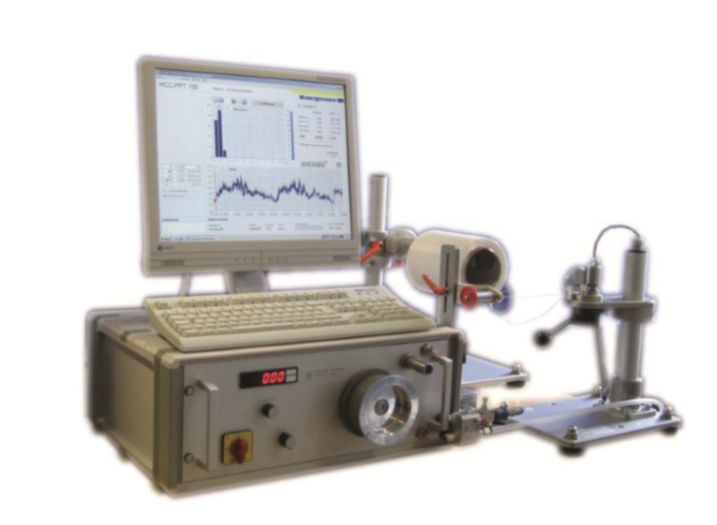

Package Performance : PPT100

Determines the unwinding characteristics of POY yarn

- Robust and stable design

- Nominal load 200 cN

- Typical natural frequency approx. 20 kHz

- Take-off speed 0 to 1200 m/min

- High zero stability and resolution

- Microsoft Windows® based data acquisition and storage

- Online display of measured data (graph or numerical value)

|

|

Abrasion : AT500

Continuous measurement of abrasion along the length of the yarn

- 200 samples/s

- 16 bit precision

- Microsoft Windows® based data acquisition software

|

|

Friction : µ-Meter

Examination of fiber friction coefficients

- Speed range: 0 – 300 m/min

- Tensile force: max. 200cN (higher on request)

- Software-based numerical and graphical analysis with Microsoft Excel® interface

|

|

Shrinkage : TST LITE

Manual measurement of shrinkage one (1) sample at a time

- Shrinkage measurement

- Temperature ramps possible

- Recording the entire test – displaying corresponding graphs

- Complies with ASTM D4974, D5591 and EN 13844

|

|

Shrinkage : TST2

Automated measurement of shrinkage and shrink force of two (2) sample at the same time

- Highest effiicienty by testing 2 samples in a single test run

- Shrinkage measurement

- Shrink Force measurement

- Temperature ramps possible

- Fully automated measurement

- Recording the entire test – displaying corresponding graphs

- Complies with ASTM D4974, D5591 and EN 13844

|

|

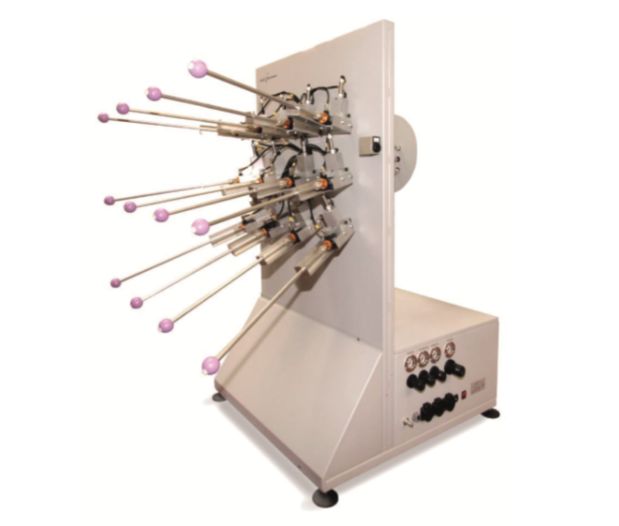

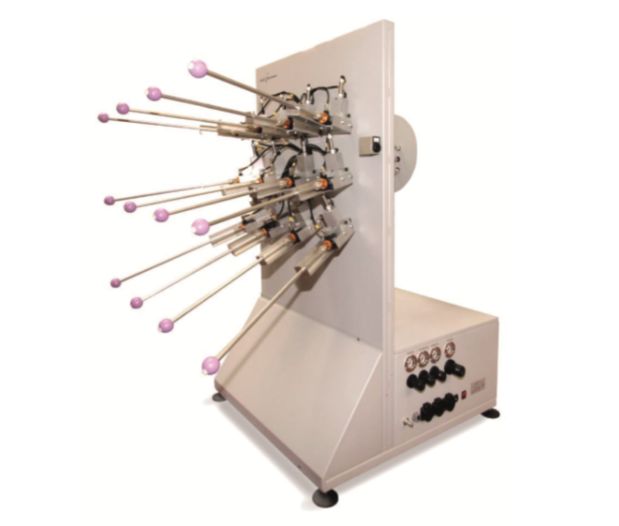

Shrinkage : TST510/250

Automated measurement of shrinkage and shrink force of ten (10) samples simultaneously

- Highest effiicienty by testing 10 samples in a single test run

- Shrinkage measurement

- Shrink Force measurement

- Temperature ramps possible

- Fully automated measurement

- Individually programmable test sequences

- Recording the entire test – displaying corresponding graphs

- Complies with ASTM D4974, D5591 and EN 13844

|

|

Forced Hot Air Ovens

Professional forced ventilation and natural convection ovens

- Ideal for all thermostatic applications where a specific precision is needed

- Temperature Range up to 280°C

- Available in 7 different sizes

|

|