Nonwoven Testing

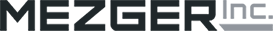

Spin Finish : ALFA 500Spin finish level determination (OPU%), based on the extraction method - ppm of carbon particles

|

|

Spin Finish : NMRSpin finish level determination (OPU%), based on the NMR method

|

|

Spin Finish : Oil ExtractionManual apparatus to determine oil content of fibers, yarn and nonwovens Digital temperature controller reaches the required set points in about 15 minutes |

|

Liquid Strike Through : LISTER ACLiquid strike through test according to EDANA/INDA WSP 70.3 (former ERT 150), (ISO 9073-8) and WSP 70.7 (former ERT 153), (ISO 9073-13) is automated measuring penetration properties.

|

|

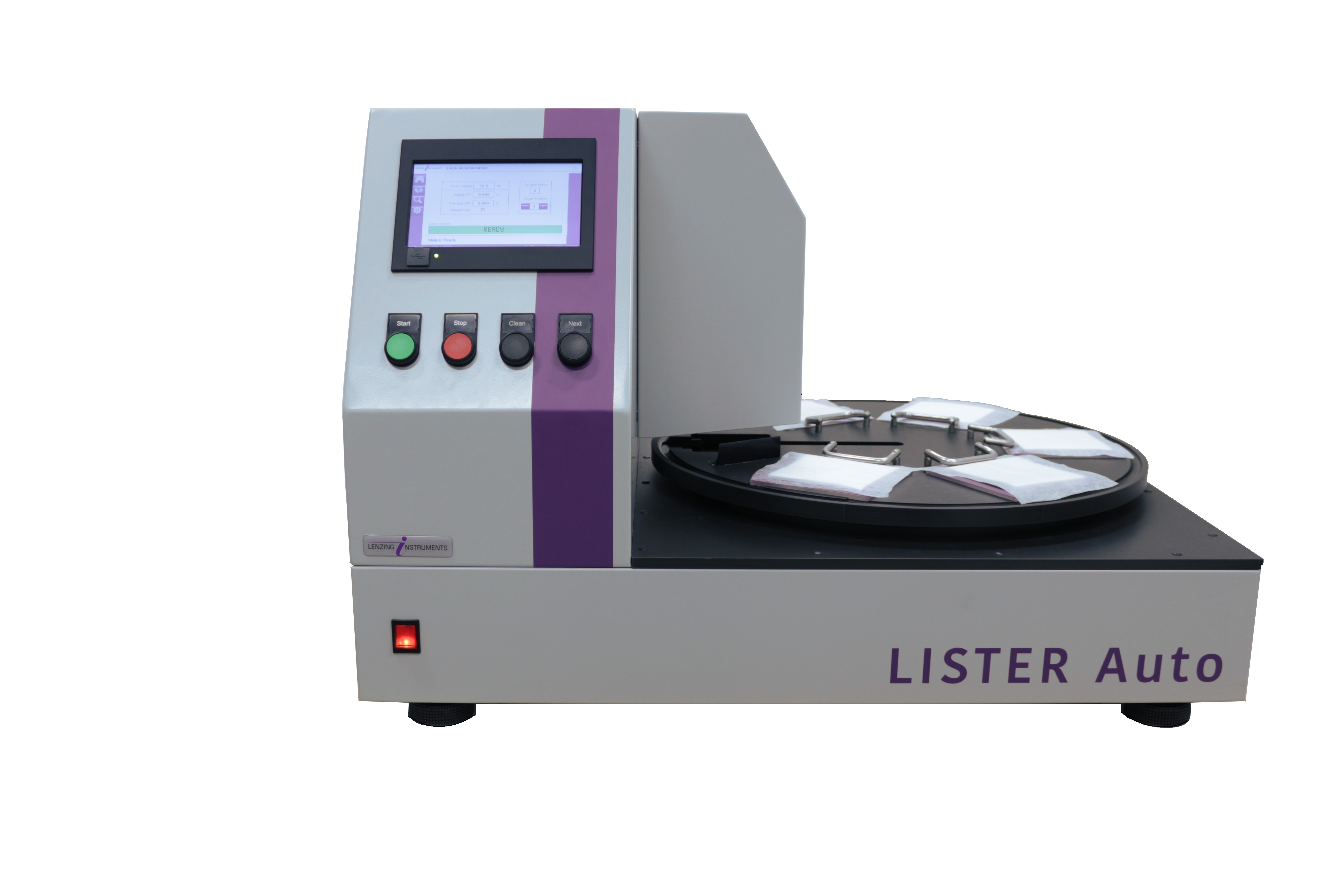

Liquid Strike Through : LISTER AC AUTOLiquid strike through test according to EDANA/INDA WSP 70.3 (former ERT 150), (ISO 9073-8) and WSP 70.7 (former ERT 153), (ISO 9073-13) is automated measuring penetration properties.

|

|

Liquid Strike Through : LISTER CARELiquid strike through test for rate of acquistion testing of diapers and pads.

|

|

Re-Wet : Wetback TesterMeasuring rewet properties according to EDANA/INDA WSP 80.10 (former ERT 151) and WSP 70.8 (former ERT 154) and ISO 9073-14 – with reliable comparability of test conditions

|

|

Re-Wet : Manaul Baby Weights |

|

Run Off TesterRunoff test in accordance to EDANA/INDA WSP 80.9 (ERT152.2). for standardized and reproducible characterization of the run-off properties. |

|

Spray Impact TesterTest Stand for measuring Spray Impact on woven and nonwoven fabrics. According to AATCC and INDA standards. |

|

Liquid Absorption BasketWire basket to determine liquid absorption capacity. According to ISO12625-8 Dimensions: 50 x 80 mm +/-0.1 mm Weight: 30 +/- 0.1 g Part no.: 3213058 |

Error Message |